Improve Cable Assembly Testing throughput with Combined Polarity, Insertion Loss and Return Loss

- The need to test cable assemblies

- Measuring polarity

- A unique feature: combine polarity with IL/RL

- Simplified process and improved accuracy

- Typical setup examples

The backbone of any optical network are the thousands of optical fibers and their connections, namely patch cords. Having good quality cables is essential for efficient communication. This means testing the performance of three key parameters must be done on 100% of cables sold. Those parameters are polarity (also known as fiber mapping), insertion loss (IL) and return loss (RL).

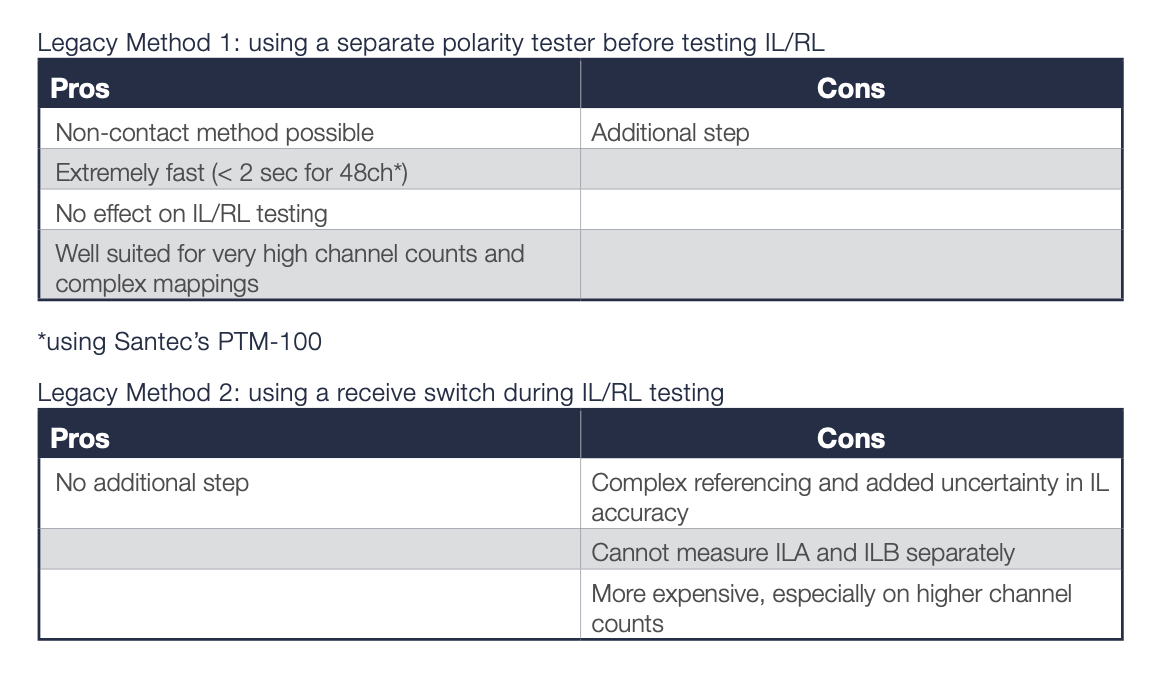

In the last decade, cable assembly manufacturers have mostly shifted towards using the light source power meter (LSPM) method to measure IL and optical time domain reflectometry (OTDR) to measure RL thanks to being “mandrel-free”. However, two different methods are still used for verifying polarity.

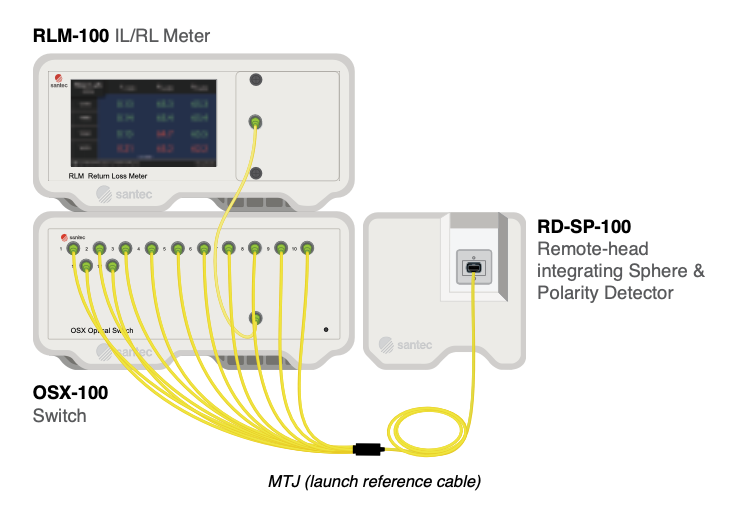

Newly released in 2024, Santec’s award winning RD-SP-100 combines the ability to measure polarity and IL in a single remote-head detector, simplifying your test setup and increasing your throughput. For the operator, the process is effectively the same as when measuring only IL and RL. The unique addition of the polarity detector in the same enclosure as the integrating sphere detector is what allows the RD-SP to do both in a single step.

For most applications, the test procedure depends on

whether you need to measure ILA and ILB separately

or if ILTotal is sufficient. If measuring ILTotal only, the

simpler Dual MTJ (master test jumper) method is

recommended. This is often used for incoming quality

inspection or short cables and cassettes. However,

if the loss at each connector must be measured

separately, the Single MTJ method is the most

accurate procedure.

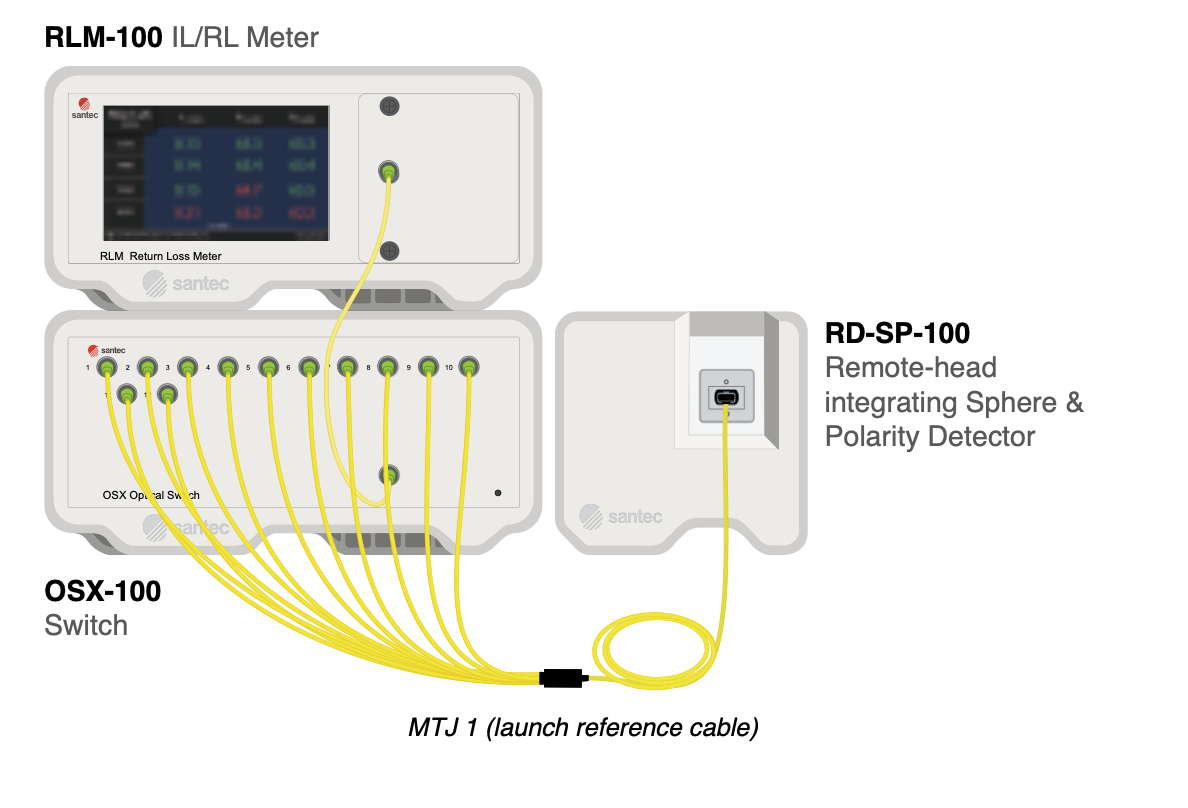

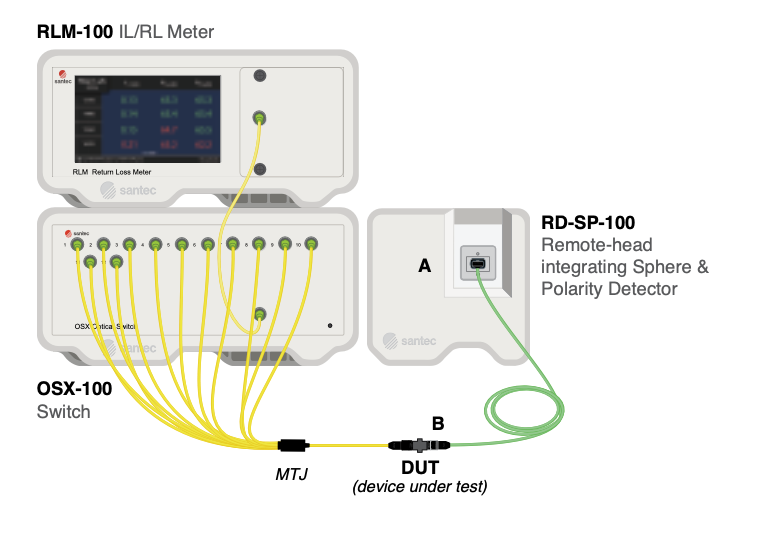

Dual MTJ Method

Step 1. Reference IL and length on the launch MTJ only

Step 2. Connect the DUT and the receive MTJ then measure Polarity, ILTotal, RLA, RLB and RLTotal

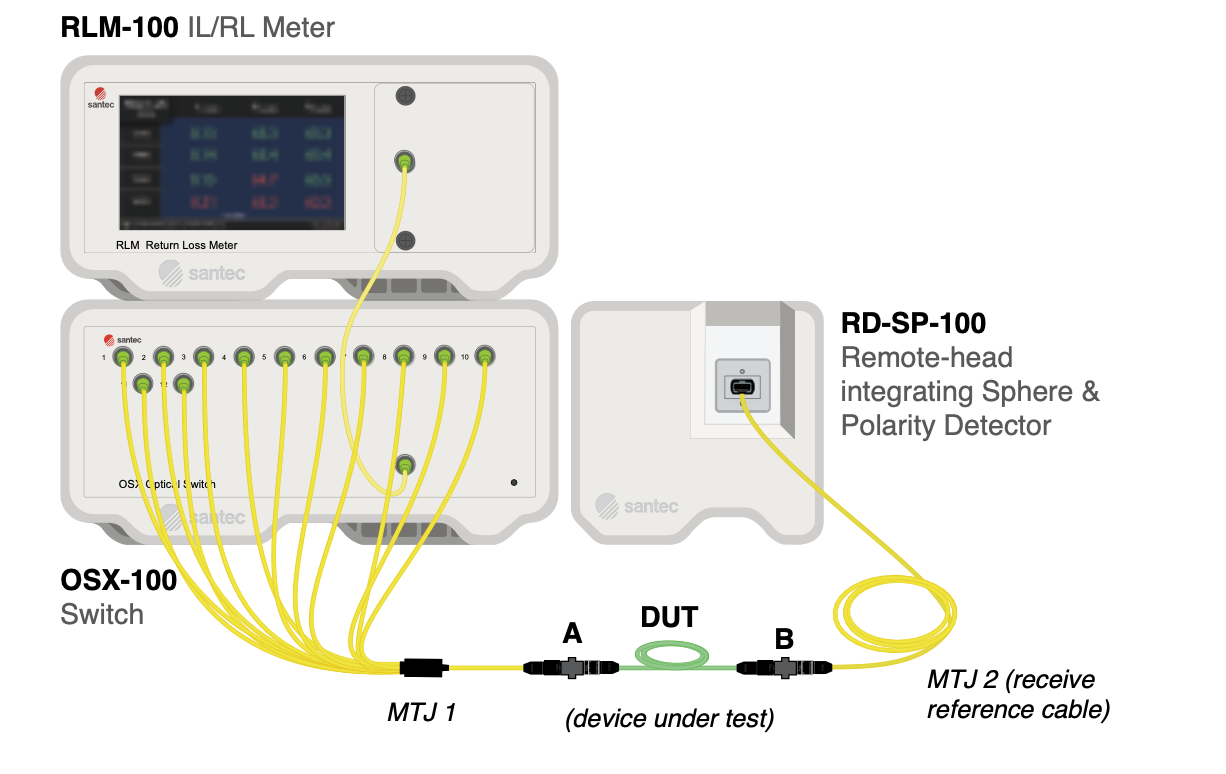

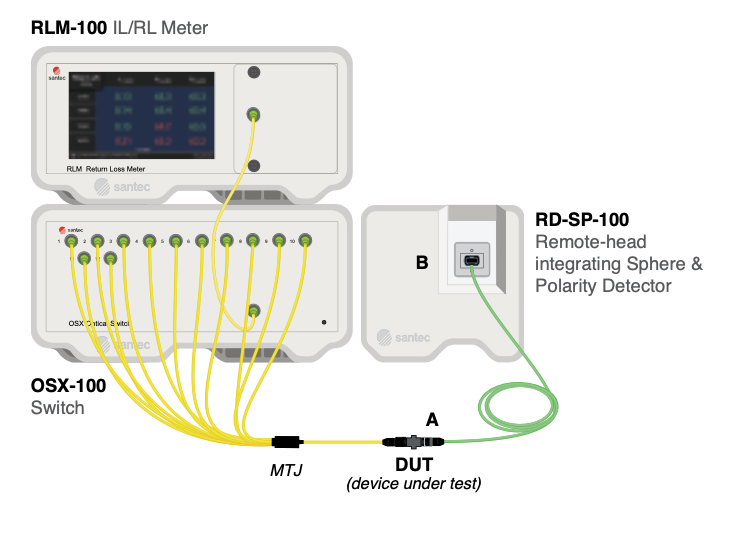

Single MTJ Method

Step 1. Reference IL and length on the MTJ

Step 2. Connect the DUT then measure Polarity, ILA and RLA

Step 3. Flip the DUT then measure ILB and RLB

Note: you can configure the test plan to check polarity before IL/RL to get a quick pass/fail on polarity in the first few seconds. If polarity is good, the software automatically continues without any operator intervention. This fast fail method makes your testing efficient, so you don’t waste time measuring IL/RL on a cable with incorrect mapping

Santec’s RD-SP-100 offers an efficient solution

for cable assembly testing by integrating polarity

measurement with IL/RL in a single step. This

innovative approach not only reduces the testing

process complexity but also enhances throughput,

providing a streamlined experience for operators.

Cable assembly manufacturers can now achieve faster

testing cycles and maintain high-quality standards,

ultimately supporting the reliable performance of

optical networks.