Power repeatability <+/- 0.02 dB

PDL repeatability +/- 0.03 dB

- STS

Swept Test System

- Real-time power referencing

- Accurate WDL / PDL characteristics measurement

- High power repeatability < ±0.02 dB

- High PDL repeatability ±0.03 dB

- High wavelength resolution and accuracy

- Multichannel measurement is available

- Convenient set up of measurement parameters

- Data analysis

Overview

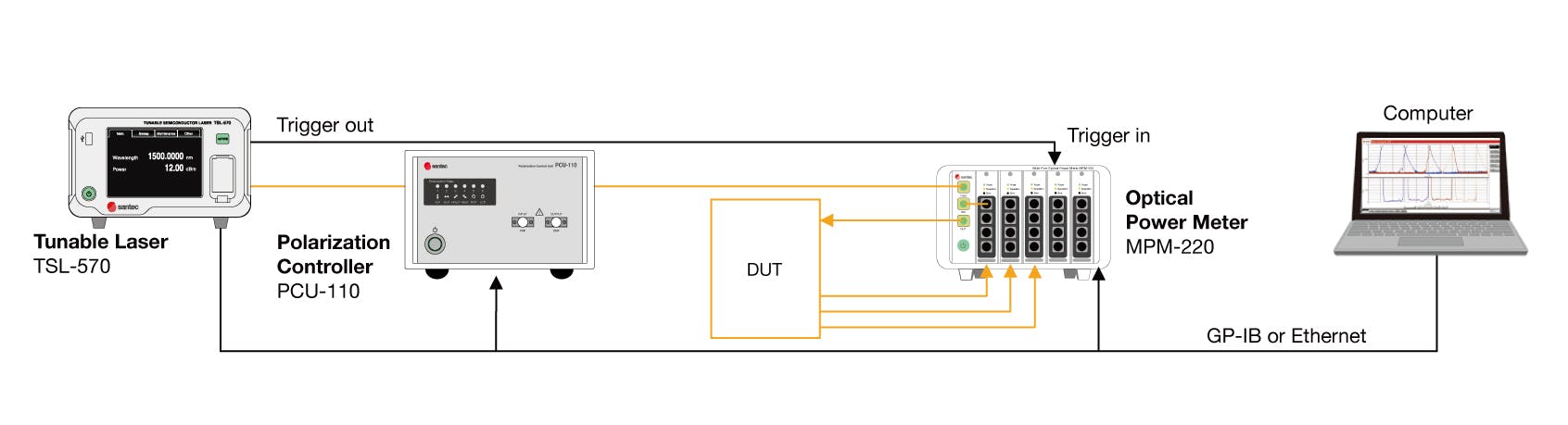

Santec’s Swept Test System has been developed to streamline photonic testing, providing a complete solution where high-speed analysis, high resolution and accuracy are key. Combining one of Santec’s tunable lasers (TSL-775 or TSL-570) with an optical power meter (MPM-220), a polarization control units (PCU-110) and custom software, the complete Swept Test System optimizes WDL and PDL measurement for use in both R&D and production environments.

Using real-time referencing, while simultaneously acquiring output power from the tunable laser and the transmitted optical power through the DUT, the system provides high accuracy in WDL and PDL analysis using the Mueller Matrix Method. Over-sampling and rescaling algorithms are used to maximize testing throughput while maintaining measurement integrity.

The Santec MPM-220 power meter mainframe can be used in conjunction with the 4-channel current meter module, the MPM-213. The Swept Test System combined with the MPM-220 and MPM-213 is suitable for measuring the performance of fiber optics components using transceiver-like photodiodes (ROSA/Coherent receiver, etc.) or optical channel monitors.

Rescaling algorithm allows for high wavelength accuracy and reduced measurement time

Modules allow up to 20 channels per chassis

Automated operation using Santec's exclusive software or available DLLs

Decades of experience to meet your custom needs

Application

- Optical characterization of components and modules:

- Tunable Filters, Interleavers, Fiber Bragg Gratings, Couplers, Splitters, Isolators, Switches, etc

- WSS and Wavelength Blockers

- DWDM components - Silicon photonic material characterization, including micro-cavity ring resonators

- Spectroscopy

- Interferometry

WDL (Wavelength Dependent Loss) Measurement

High dynamic range measurement of 80 dB or more

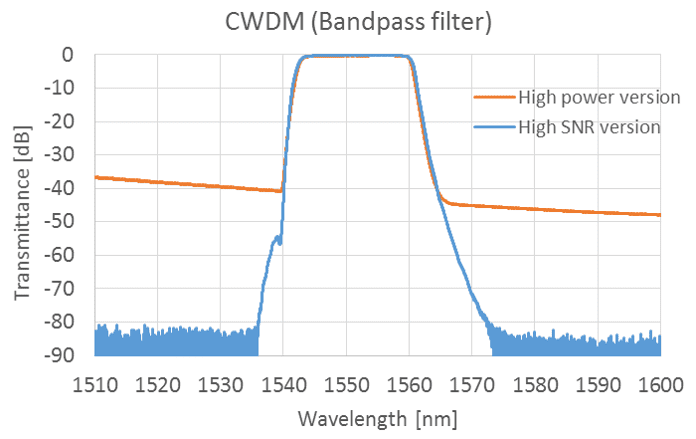

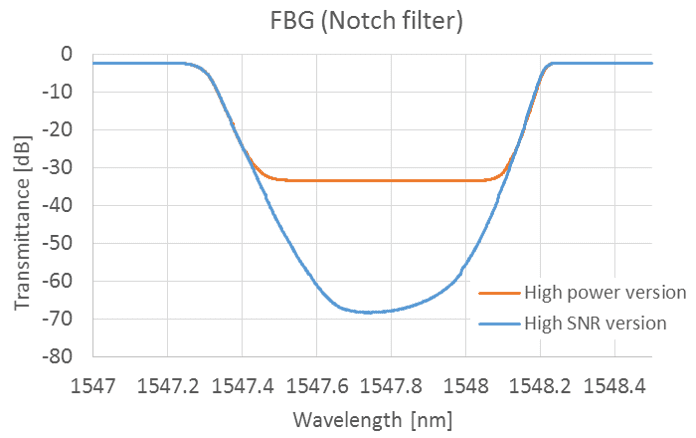

The Santec tunable laser source TSL series have been outfitted with an innovative cavity design to lower the optical ASE noise, resulting in an extraordinarily high signal-to-noise ratio of over 90 dB / 0.1 nm, while also maintaining a high output power of over + 10 dBm. The TSL series lasers are ideal for next generation components testing driven by innovations in Dense Wavelength Division Multiplexing (DWDM), passives and Wavelength Selective Switches (WSS). The following graphs show the measurement data of a CWDM filter and notch filter, (such as an FBG) respectively.

High wavelength accuracy +/- 3 pm

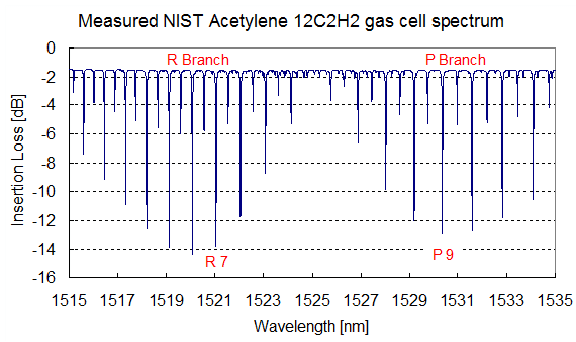

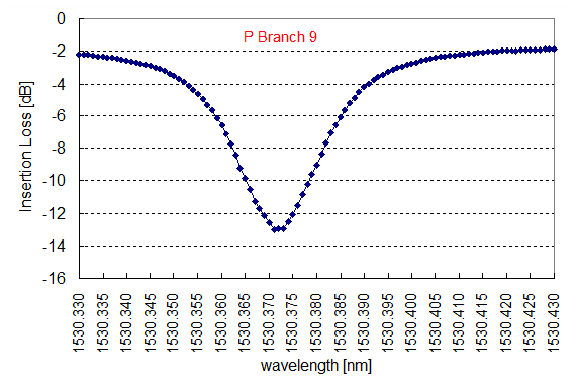

The Santec tunable laser source TSL series has been equipped with the wavelength monitor as standard, so is ideal for high precision testing of optical passive components. A measurement accuracy of less than a few pm can be confirmed by measuring the absorption lines of Acetylene (12C2H2) gas cell.

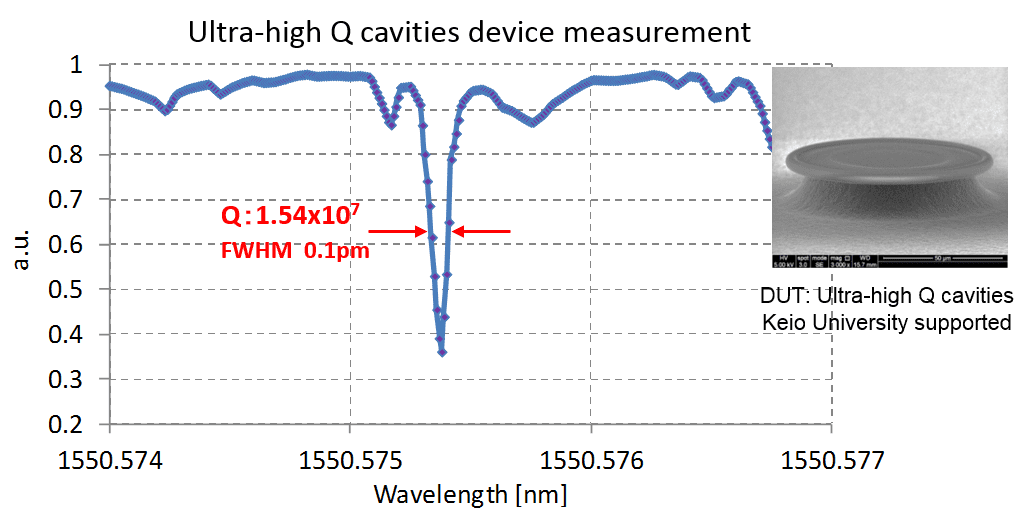

High wavelength resolution less than 0.1 pm

The Santec Swept Test System can measure not only WDL measurements of optical components (including Dense Wavelength Division Multiplexing (DWDM), AWG, Wavelength Selective Switches (WSS) and more), but also very narrow filters (i.e., High Q cavity devices) efficiently with high resolution, even during continuous sweeps.

Configuration

Polarization Dependent Loss Measurement

- Tunable Laser TSL-775 / TSL-570

- Polarization Controller PCU-110

- Optical Power Meter MPM-220

- Tunable Laser TSL-775 / TSL-570

- Optical Power Meter MPM-220

Resources

Documentation

Contact UsTechnical Whitepaper: Insertion Loss Testing Methods Explained

Why Insertion Loss Matters

Insertion loss—the reduction of signal power as it travels through optical components or fiber—is a critical factor in ensuring the performance and reliability of modern communication systems. Whether in telecommunications, data centers, photonics, or aerospace, accurate insertion loss testing is essential to minimize signal degradation, maintain data integrity, and optimize system efficiency

What You’ll Discover in This Whitepaper

This technical guide provides engineers and industry professionals with a comprehensive overview of insertion loss testing methods, focusing on accuracy, repeatability, and practical trade-offs. Learn how to:

1. Understand the Fundamentals Master the core principles of insertion loss measurement, including how it impacts signal transmission and system performance.

2. Identify and Minimize Errors Explore common sources of measurement errors—such as connector misalignment, fiber bends, and environmental factors—and discover best practices to mitigate them.

3. Compare Testing Methods Evaluate the strengths and limitations of:

- Broadband Testing: Ideal for general applications requiring quick, cost-effective measurements.

- Swept-Wavelength Testing: Offers high precision across a range of wavelengths, perfect for advanced optical characterization.

- Fixed-Wavelength Testing: Provides stability and repeatability for specific applications.

4. Optimize Test Configurations Gain insights into recommended setups for high-precision testing, including the use of tunable lasers and power meters.

5. Leverage Advanced Tools Discover how Santec’s tunable lasers, Laser Lock Pro, and optical power meters enhance measurement stability and repeatability, delivering low-uncertainty results across C-, L-, and extended wavelength bands.

Read the full whitepaper

Co-Packaged Optics – Redefining Interconnects with Precision Testing

Co-packaged optics (CPO) is revolutionizing data center and high-performance computing interconnects by integrating optical engines directly with switching ASICs. This whitepaper offers a detailed, engineer-level exploration of CPO, covering both the technological benefits and the rigorous testing requirements needed to ensure performance and reliability.

In this whitepaper, you will discover:

1. The key drivers for CPO adoption — power efficiency, bandwidth scaling, signal integrity, and form-factor optimization

2. How photonic integrated circuits (PICs) enable compact, high-density optical I/O in CPO architectures

3. Thermal challenges in co-packaged designs and best practices for thermal management during testing

4. Testing strategies for CPO modules: measuring insertion loss, return loss, polarization effects, crosstalk, and more

5. Advanced measurement solutions: how Santec’s tunable lasers, polarization synthesizers, power meters, and swept analyzers (e.g., STS system, SPA-110) can be integrated into high-precision CPO validation setups

6. Practical tips for building an automated, repeatable test flow that addresses the unique trade-offs of co-packaged optics

Whether you're developing PICs for production, characterizing module-level performance, or optimizing test processes for yield and scale, this guide shows how Santec’s measurement instruments support every aspect of CPO development.

Read the full whitepaper